Construction Industry

The construction industry includes, for instance, concrete prefab to formwork and metal structures, concrete skips and prefabricated modules, pallet forks to rental equipment, and tower cranes to WC modules, amongst many other applications.

Handling and control of the tower crane must be performed by skilled operators as the risks associated with the different operations carried out are high. More importantly, these operations not only require a precise crane control, but also a well-coordinated operator and signaller work, to avoid risks related to cargo handling.

Intending to avoid risks and optimize both cargo handling and productivity, the elebia evo5 to evo25 are leading a revolution in those sectors where the use of the tower crane is essential, like the construction industry. These automatic crane hooks allow the remote engagement and disengagement of the load without requiring its direct handling. This means that work can be done in a more safely and comfortably way, also with fewer staff. Moreover, this is a highly reliable system that prevents that the load can be released once it has been engaged.

What do our clients say?...

..."There is a definite reduced operation time of the crane..."

..."The crane often had to wait until an operator travelled to the load to release the hook. Now the crane does not stand still, and there's no downtime..."

..."Murphy’s Law is true. You are at the top of the bulding and the concrete skip or the pallet fork is at the bottom… With elebia, this is no longer a problem…"

By using the elebia automatic hook, many lifting and assembly of steel structures operations are optimised, obtaining reductions in operating time, personal savings and machinery, such as baskets trucks. Thus, it is possible to assemble structures without having an operator manually release the hook.

Depending on the model and size of crane, it is advisable to do some work for installation, so that the automatic hook is properly stored and does not exceed the gauge. It is a simple customisation.

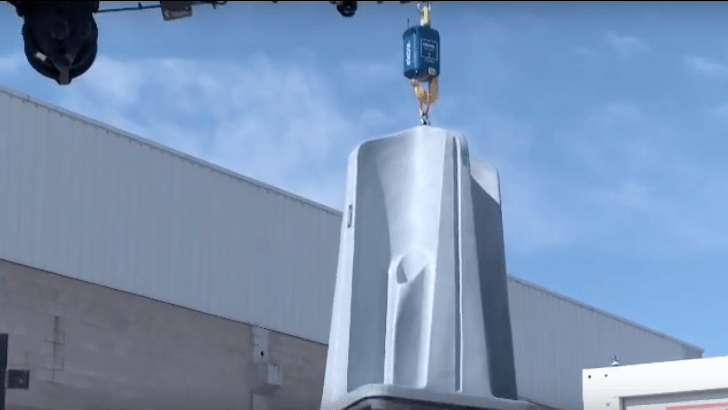

Thanks to the elebia automatic hook, loading and unloading and positioning of WC modules is done quickly and efficiently through the crane truck without a forklift.

With the use of the elebia automatic hook, you can hook and release the fork without manipulation. There is no need to get on and off the truck bed. The whole operation is performed from the crane controls.

The remote hook increases the safety of crane loading operations by preventing the operator having to manipulate the hook and load. There is also the possibility of installing the remote control inside the crane.

*(Pictured is a 1st generation automatic hook)

The elebia system allows crane mounted trucks through the entire process of loading, unloading and lifting of the silo safely solving any limitations.

Safety Benefits:

- No need to be near the load or the crane boom

- Avoid injuries or chronic illness as it is not necessary to repeatedly climb up and down the truck bed.

- The elebia automatic hook is fail-safe. It is not possible to drop the load while suspended.