Guide to Safe Slinging Practice

Guide to Safe Slinging Practice

31 January, 2024

Índex

ToggleGuide to Safe Slinging Practice: Ensuring Secure and Effective Lifts

When it comes to heavy lifting in industries such as construction, manufacturing, or shipping, the importance of safe slinging practices cannot be overstated. Properly executed slinging not only ensures the safety of the operators but also protects the integrity of the load being lifted. In this comprehensive guide, we will delve into the key aspects of safe slinging, offering valuable insights for a secure and efficient lifting operation with our Automatic Release Hooks.

Understanding Safe Slinging:

1. Selecting the Right Sling:

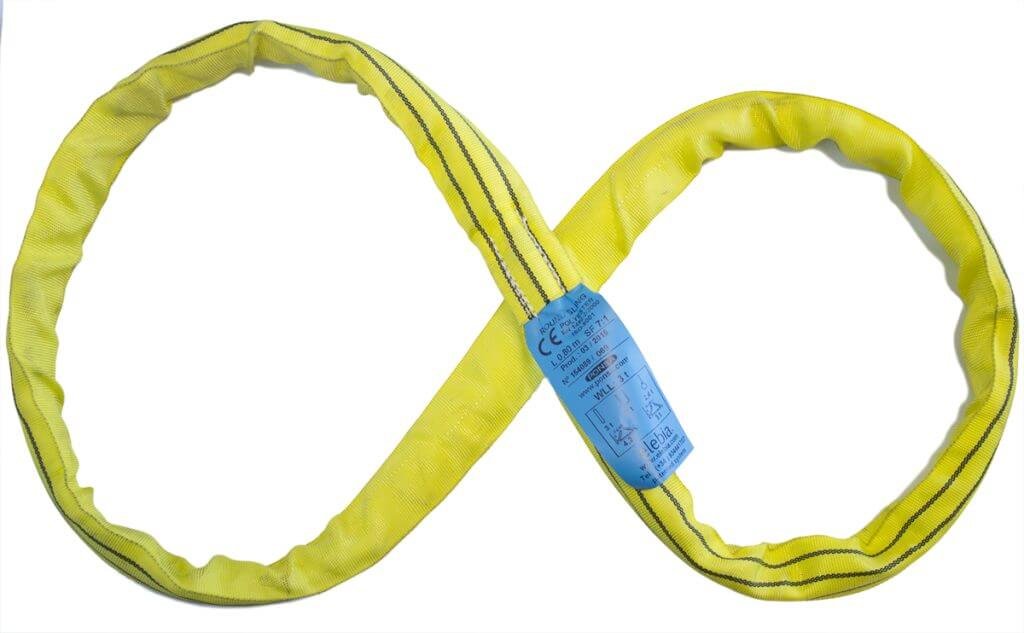

The first step in slinging is choosing the appropriate sling for the job. Factors such as the type of load, weight, and environmental conditions play a crucial role. Options include wire rope slings, chain slings, and synthetic web slings, each with its unique characteristics.

2. Inspecting the Sling:

Regular inspections are paramount to safe slinging. Before each use, visually inspect the sling for signs of wear, cuts, or any damage. Pay special attention to fittings and connections. If any issues are detected, replace the sling immediately.

3. Proper Sling Application:

Understanding the load’s center of gravity is crucial for safe slinging. Ensure the load is balanced and properly rigged to prevent any shifting during the lift. Attach the sling to appropriate lifting points on the load and avoid sharp edges that may compromise sling integrity.

4. Calculating Load Weight:

Accurately determining the weight of the load is fundamental for automatic lifting. Overloading a sling can lead to catastrophic failure. Refer to load charts and weight ratings to ensure the sling’s capacity matches or exceeds the load weight.

5. Safe Lifting Techniques:

Operators should be trained in proper lifting techniques to prevent accidents. Use tag lines to control load swing, avoid sudden movements, and communicate effectively with other team members involved in the operation.

6. Securing the Load:

After the lift, secure the load properly to prevent unintended movements during transportation. Double-check all connections, and if necessary, use additional securing equipment to enhance load stability.

Linking to Safe Slinging Equipment:

To ensure your slinging practices are supported by reliable equipment, consider exploring our range of high-quality slings. Our Safe Slinging Collection includes a variety of options designed for different lifting scenarios. From durable wire rope slings to versatile synthetic web slings, each product is engineered to meet stringent safety standards.

Conclusion:

Prioritizing safe slinging practices is not just a legal requirement but a moral responsibility. By adhering to the guidelines outlined in this comprehensive guide, you contribute to a safer working environment and protect valuable assets. Remember, a commitment is an investment in the well-being of your team and the success of your operations.

For more information on safe slinging or to explore our range of slinging equipment, feel free to contact us. Safe lifting starts with the right tools and knowledge – let’s lift securely together!